Customized tools

Product development in partnership with our customers

Properly designed electrical connectors and terminals include crimp characteristics and attributes to ensure performance in critical applications. The quality and consistency of a wire crimp connection relies heavily on the quality and consistency of the tooling used to produce that connection. Telecommunications, Electrical Power, Aerospace, or Automotive – regardless of industry, standards were written to set a precedence to ensure safety, reliability, repeatability, and overall performance of a crimped electrical connection.

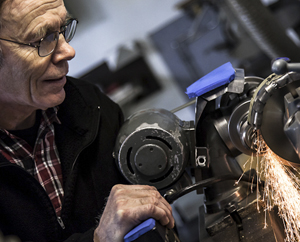

Pressmaster is a world leader in this area of hand tool development. Our engineers define project requirements in close cooperation with each customer. Prototypes are manufactured and performance monitored in a laboratory environment with cross section images and crimp pull-out tests. New tool frames are thoroughly tested to insure that they will fulfill the requirements throughout their lifespan.